Product Series

AMZ Rotor Pump

Classification:

keywords: AMZ Rotor Pump

Sanitary valves are key equipment widely used in industries such as pharmaceuticals, biotechnology, and food processing

E-mail:

Telephone:

Details

1、 Definition of Sanitary Valves

Sanitary valves refer to valves that meet strict hygiene requirements, and their design, manufacturing, and material selection are all based on meeting hygiene standards in industries such as food and medicine. This type of valve has the characteristics of no dead corners, easy cleaning, and corrosion resistance, ensuring the purity of the fluid during transmission.

2、 The function of sanitary valves

1. Flow control: Sanitary grade valves can accurately control the flow of fluids as needed, ensuring the stability of the production process and the quality of the product.

2. Preventing backflow: Valves can prevent fluid backflow and prevent pollutants from entering the production process.

3. Automation control: Some sanitary valves have automation control functions and can be linked with other equipment to achieve intelligent management of the production line.

3、 The role of sanitary valves in safeguarding human health

Sanitary valves, as important equipment in industries such as pharmaceuticals and food, play a crucial role in ensuring human health. Specifically, its role is reflected in the following aspects:

1. Ensure product safety: The application of sanitary valves can ensure the purity of fluids during transmission, thereby ensuring product safety.

2. Preventing cross contamination: The design of valves can prevent cross contamination between different fluids and reduce the risk of product contamination.

3. Improve production efficiency: Sanitary valves are easy to clean and maintain, which can greatly improve production efficiency and reduce production costs.

4. Reduce health risks: By precisely controlling flow and preventing backflow, sanitary valves can reduce potential risks to human health during the production process.

In short, sanitary valves play a crucial role in industries such as pharmaceuticals and food. Understanding and correctly applying sanitary valves is of great significance for ensuring product quality and human health. With the advancement of technology and the increasing demand for product safety, sanitary valves will play a more important role in the future.

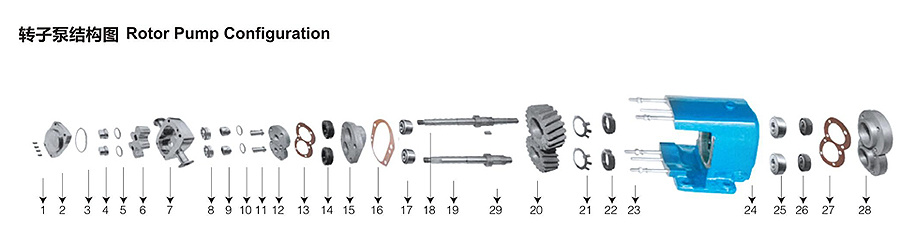

21 .Stop washer 22.Cap 23.Screw24.Pump body 25. Bearing 26 .Rubber oil seal 27 .Seal gasket 28.Bearing cover 29.Pin

RELATED PRODUCTS

Sanitary valves are key equipment widely used in industries such as pharmaceuticals, biotechnology, and food processing

GET MORESanitary valves are key equipment widely used in industries such as pharmaceuticals, biotechnology, and food processing

GET MORESanitary pneumatic straight ball valve

Sanitary valves are key equipment widely used in industries such as pharmaceuticals, biotechnology, and food processing

GET MOREPneumatic butterfly anti mixing valve

Sanitary valves are key equipment widely used in industries such as pharmaceuticals, biotechnology, and food processing

GET MORELEAVE US A MESSAGE

If you have any need, please feel free to contact us